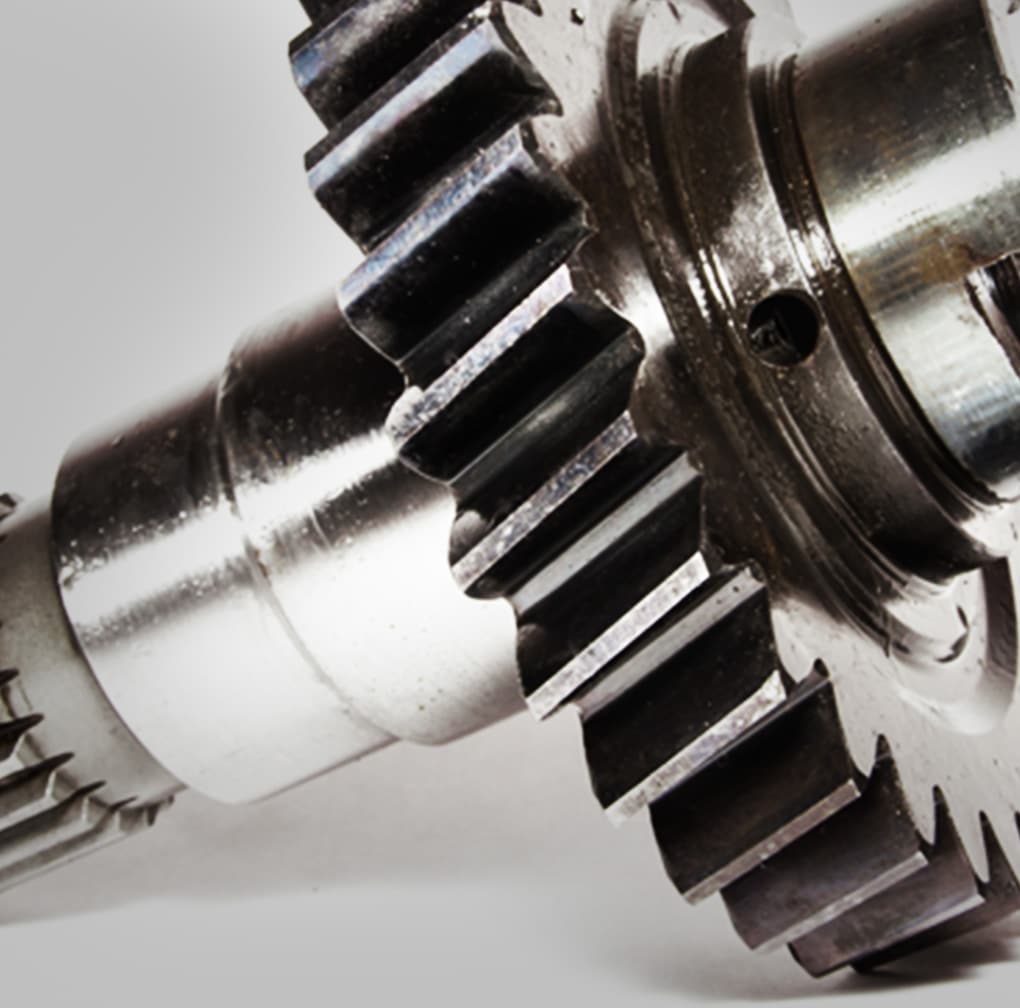

Mechanical Finishing

Pioneer offers a variety of mechanical pretreatment finishes to provide aesthetic appearance, adhesion of top coats, stress relief, and to remove sharp edges.

Pioneer offers a variety of mechanical pretreatment finishes to provide aesthetic appearance, adhesion of top coats, stress relief, and to remove sharp edges.

Pioneer offers a variety of blasting options to meet pretreatment and texture requirements for various finishes. From high volume tumble blast and spinner hanger shot blast to large cabinet individual part blasting. Pioneer removes rust, scale, and other contaminates from your critical part surface prior to the application of your engineered coating system.

With a variety of different equipment applications Pioneer can handle any type of size and part.

Blasting is a “one step” method that strips, cleans and etches all at once.

Standard Specifications

TT-C-490 Method I

LMN 331-2

TES-1401

Performance Benefits

Coating Adhesion

Cosmetic Appearance

Receptive Metals

Aluminum Alloy

Aluminum Casting

Common Types of Media

Stainless Steel

Shot

Grit

Aluminum Oxide

Glass Bead

Sand

If you have specific media requirements such as Ceramic, Plastic, Walnut, etc. please contact Pioneer at 877-721-1100.

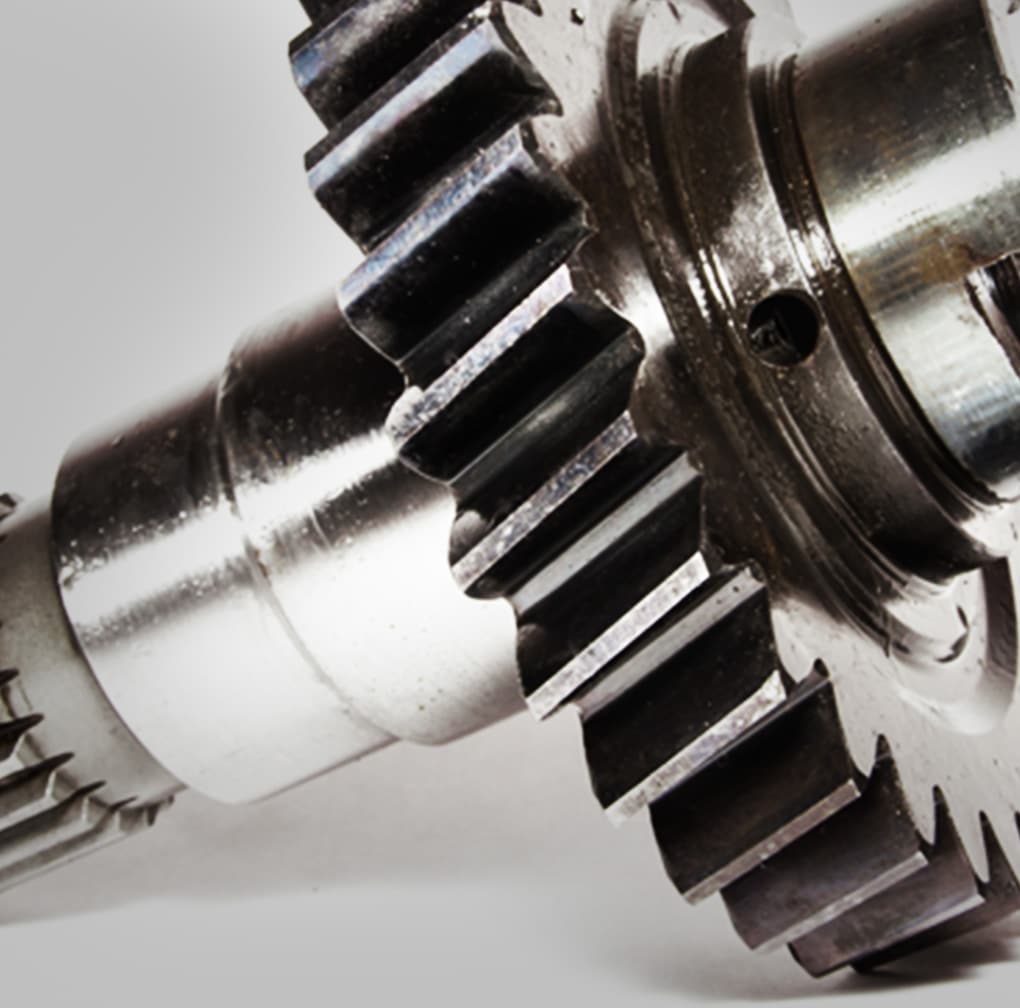

Deburring is the process of removing sharp burrs to smooth both large and small parts edges. Deburring creates a softened edge on metal parts that is safe to handle and improves bonding of plating or other coating systems on edges.

Electropolishing is an electro-chemical process that smoothens, polishes, deburrs and cleans stainless steel, in an electrolytic bath. The process selectively removes high points on metal surfaces, giving the surface a high luster. Conventional mechanical finishing systems tend to smear, bend, and stress the crystalline metal surface to achieve smoothness or luster. Electropolishing offers the advantage of removing metal from the surface producing a unidirectional pattern that is both stress and occlusion free, and microscopically smooth.

Standard Specifications

ASM2700

ASTM B117

QQ-P-35

Performance Benefits

Microscopically Smooth

High Luster

Receptive Metals

Stainless Steel

Max Part Size

4′ x 2′ x 2′